WHITEPAPER

Energy Solutions

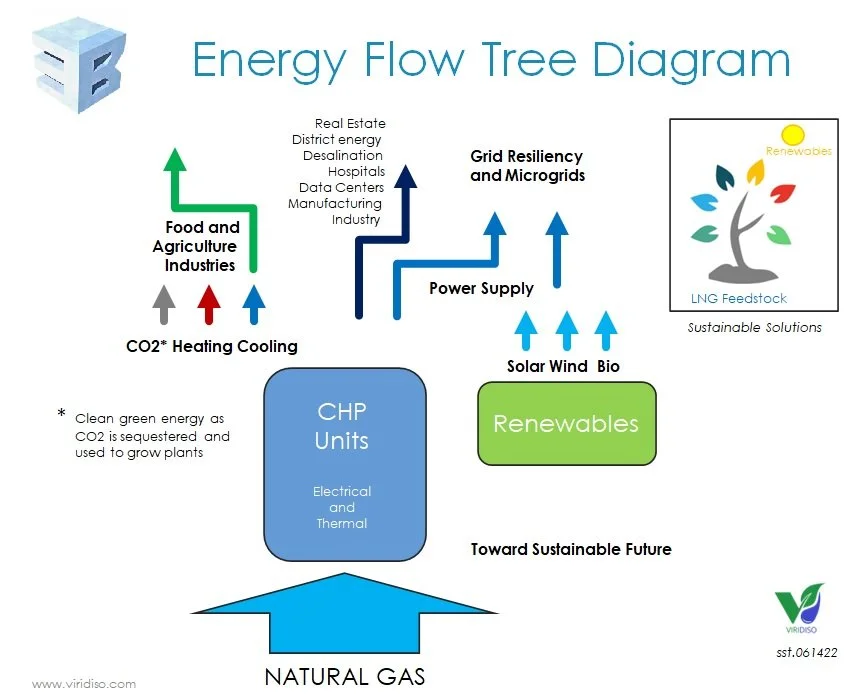

Without energy, there is no economic growth. Access to power is crucial for progress, as it opens new growth opportunities. Our goal is to bring sustainable, reliable sources of electrical and thermal energy with minimum impact on our ecosystem. Our team is solving critical challenges on our planet by bringing in cleaner and cheaper LNG energy to produce a robust, reliable supply of electricity using high-efficiency CHP generators while simultaneously delivering electricity from renewable sources, such as solar, wind, hydro, and biomass, combined with an innovative power storage system to provide comprehensive energy solutions.

Our energy solutions are based on sustainability, resiliency, and economics. First, sustainability means pulling together complex concepts of net-zero, resource efficiency, decarbonization, carbon neutrality, carbon negative, and green economy. Next, resiliency means providing an energy system that can work reliably 24 hours a day, 365 days a year, regardless of the weather or climate. Finally, economics means leveraging on the economy of scale and extracting collective values, treating processes collectively, not as a silo, where the waste product of one process becomes the feedstock of another, so nothing is wasted.

SUSTAINABLE ENERGY GENERATION:

Decarbonization is not adding industrial CO2 into the air and reducing human-made CO2 emissions. As CO2 is a greenhouse gas that traps infrared radiation and causes heat to accumulate, it is prudent not to add more CO2 into the atmosphere. As plants and the ocean can only consume about half of the present anthropogenic CO2 through photosynthesis, adding CO2 beyond nature’s ability to digest will accelerate buildup above 400 ppm.

Carbon Neutral is a status quo outcome of decarbonization, where no net CO2 is added into the atmosphere. Nothing changes for the better or worse. Sequestering CO2 from a combustion process is carbon neutral. For example, capturing CO2 from the exhaust of a CHP generator fueled by LNG is a carbon-neutral process where no net CO2 is added into the atmosphere.

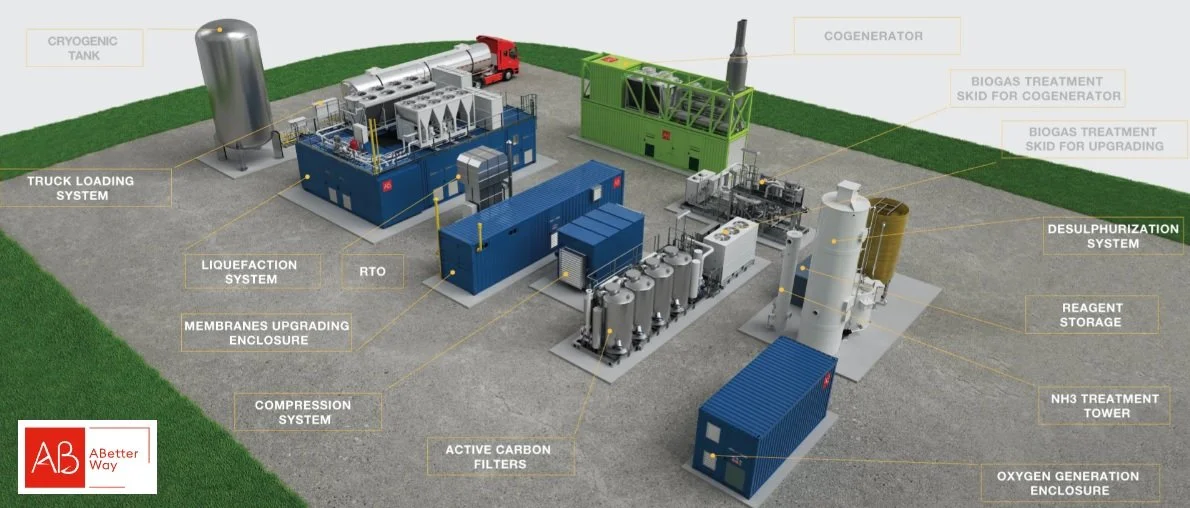

Carbon Negative is where net CO2 is removed from the atmosphere. In nature, a forest is carbon-negative, where CO2 becomes plant matter. Using Renewable Natural Gas (RNG) combined with CO2 capture in CHP is carbon negative. The decomposing landfill or biowaste naturally produces methane. If its renewable natural gas is used in power production, and the CO2 is sequestered, it results in a net removal of GHG. Other carbon-negative activities are reforestation by net planting down trees, using biochar to increase soil carbon content, or using captured CO2 as agriculture feedstock or converting it into useful products such as bioplastics.

Net-zero: net-zero is defined as negating the impact of greenhouse gases by human activity by absorbing them from the atmosphere. It refers to the overall balance of GHG emissions produced and taken from the atmosphere.

We define net zero even further as a bubble within our activity where we do not burden our ecosystem in air, ground, and water.

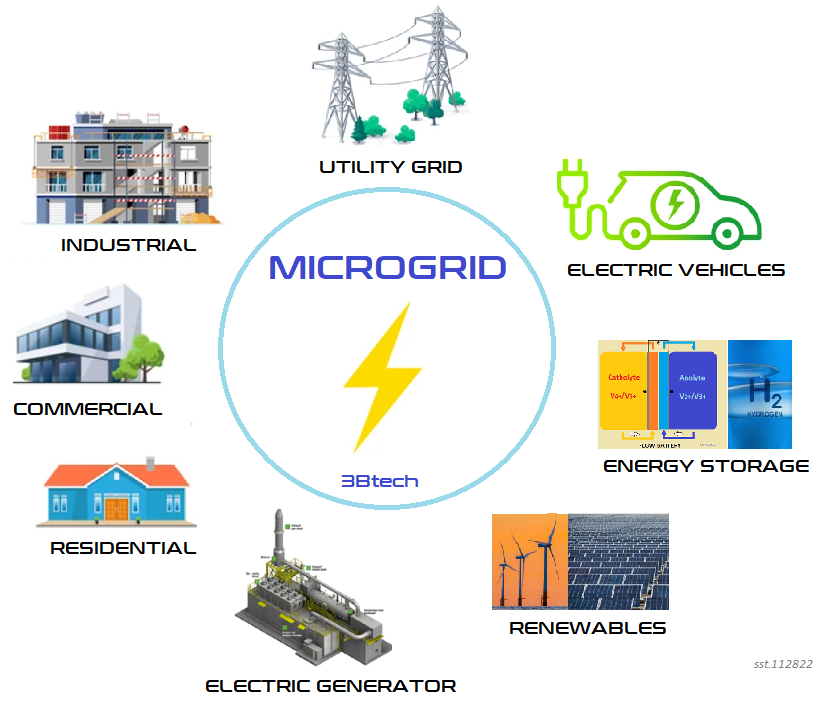

SMART ENERGY AND MICROGRID:

Smart Microgrid to provide the community with grid resiliency by combining clean, reliable natural gas CHPs and turbine cogeneration with green renewable solar, wind, and biomass waste-to-energy resources. The advanced energy management system will efficiently generate and distribute electricity locally and into the power grid. To accelerate energy decarbonization, we recycle CO2 for the agro-industry, pursue net-zero emissions and carbon neutrality, and adopt technologies toward the hydrogen economy.

WASTE HEAT AND CO2 RECYCLING:

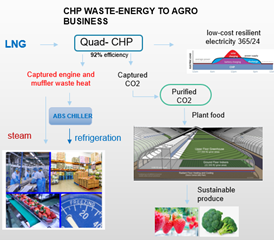

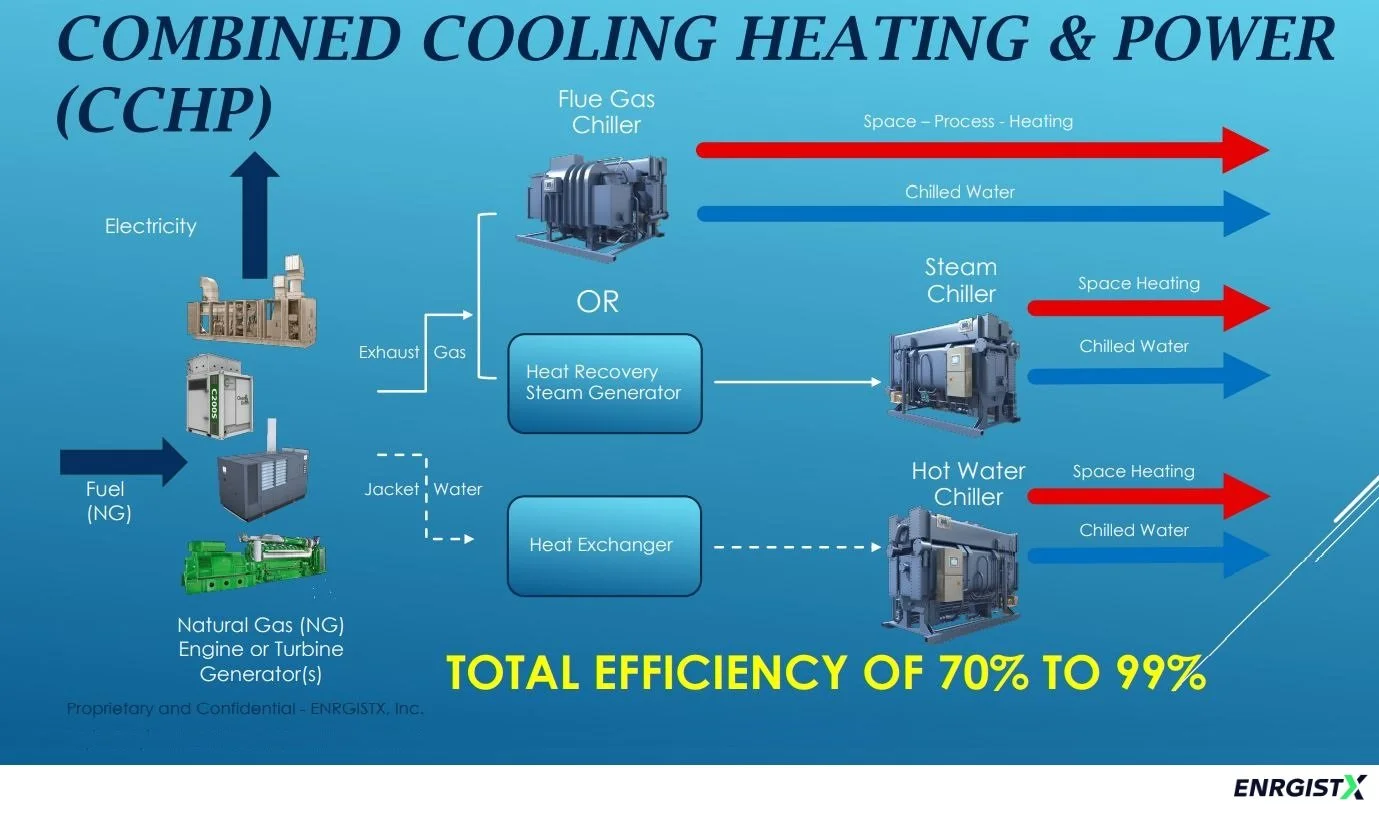

Combined Heating and Power (CHP) is a high-efficiency energy cogeneration system. that generates electricity and captures the waste heat for practical applications. CHP natural gas quad-generation (4G) processes deliver electricity, sequester CO2, capture engine waste heat, and convert heat into 40F chilled water via an absorption chiller. CHP requires less fuel for given power output. Its waste heat can be used in food processing, beverages, hospitals, greenhouses, and district heating/cooling. Typical fossil-fueled power plants in the United States have 33% efficiency. Our CHP system has an impressive overall 92% electrical and thermal efficiency.

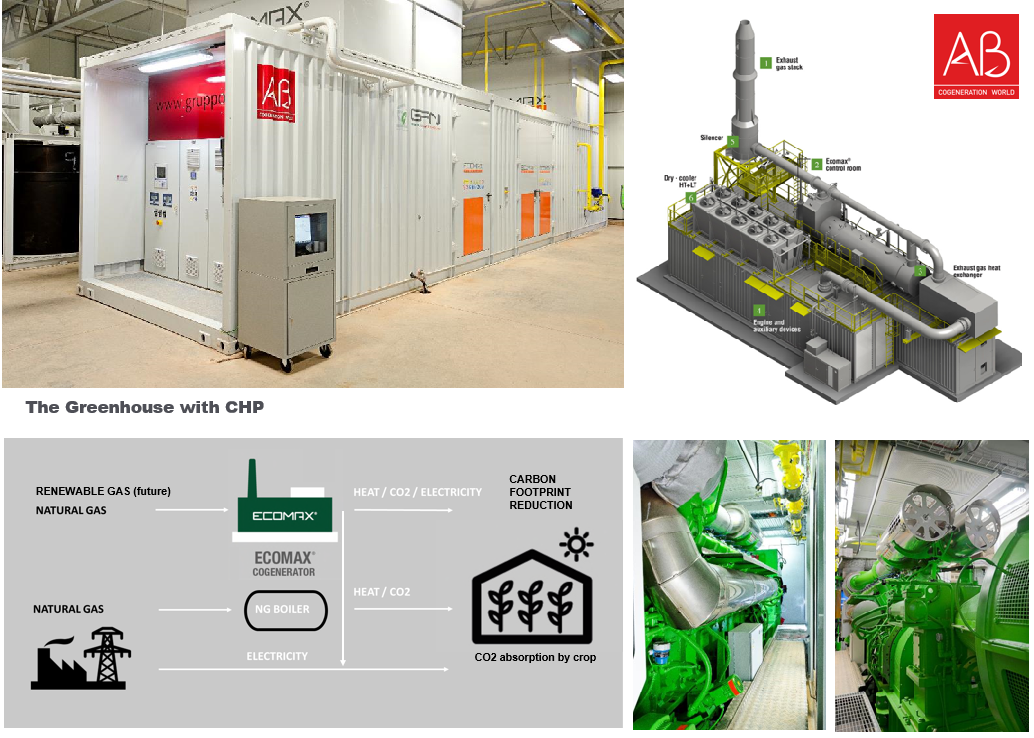

CHP WASTE-ENERGY TO AGRO BUSINESS

The combination of CHP and greenhouse agriculture is ideal as the thermal and CO2 waste products could be fully utilized. The resulting steam, hot water, and chilled water can be used in the greenhouse and further agri-business processing. The CO2, instead of being discharged into the atmosphere, is being captured, cleaned, and used as nutrients to grow the plants, therefore completing the cycle of sustainability with net zero and carbon neutrality.

CLEAN LIQUID NATURAL GAS:

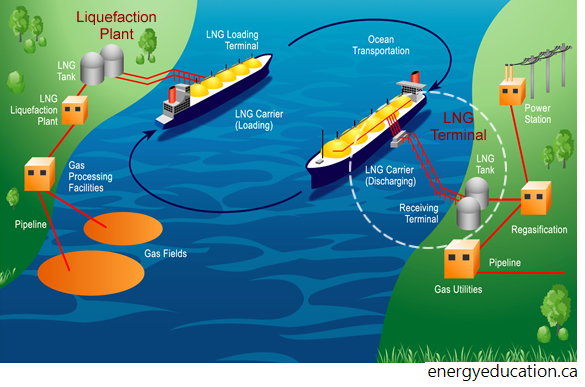

Natural gas is commonly used as fuel in residential, commercial, and industrial. In its liquid form as Liquified Natural Gas (LNG), it is kept at -260F (-162C) at atmospheric pressure. Its volume as a cryogenic liquid is 1/600 of the volume of gas in its vapor state. This small volume of liquid makes it economical to transport. When ready to be used, LNG can be returned to its gaseous state by a vaporization process called gasification. Alternatively, natural gas can be kept in a tank as Compressed Natural Gas (CNG) with 1/100 volume of its gaseous state at room temperature and pressure of 3200 psi.

LNG and CNG Supply Chain:

Our team serves and operates in the upstream to downstream natural gas supply chains. We provide custom and state-of-the-art solutions to support fuel distribution and power generation worldwide. We provide service, transportation, storage, and utilization of LNG and CNG.

Starting from the gas deposit in the earth, crude natural gas mixtures are filtered and separated to produce methane, among other gases. This clean natural gas can then be liquified as LNG, compressed CNG, or piped for distribution.

Our partner, Corban Energy Group (CEG), specializes in the design, manufacture, distribution, installation, operation, and maintenance of vessels used in cryogenic natural gas. As a custom-built large tank and container LNG manufacturer, CEG thoroughly tested the vessels under harsh conditions to meet international standards.

CEG products include liquefaction plants, Factory-built Bulk Storage Tanks, Intermodal ISO Tank Containers, Marine Cargo and Bunkering Tanks, Site-build Flat-Bottom Tanks, and CNG Fueling Stations.

CEG produces vertical and horizontal tanks with a capacity of up to 1400 m3 (370,000 gallons). These double-wall tanks, with a vacuum in between, ensure the LNG inside is kept cryogenically in any weather conditions. These tanks have a 30+ years lifespan and a superior performance Boil-Off rate of < 0.06% per day,

ISO Tank containers provide efficient and versatile means to transport LNG on the road, railcars, and barges. With a capacity of up to 16,000 gallons in 20, 40, and 53 ft lengths, these tanks are ideal for intermodal transportation and mid-term storage for up to 90+ days. ISO Tanks are ASME, DOT, CSC, and IMDG-approved.

For large-capacity LNG long-term storage, an onsite Flat-bottom Tank can be constructed, available in various sizes up to 200,000 m3 (53 million gallons). These tanks are designed and built to be highly efficient, safe, and easy to maintain.

LNG gasifiers convert liquid natural gas back into gas. We provide both ambient and electrically heated vaporization system, each up to 600,000 standard cubic feet per hour.

For CNG, where natural gas is compressed at room temperature to 1/100 of its volume, we have a complete storage and delivery system. Since already at room temperature, CNG can be dispensed directly without gasifiers. CNG can be used in place of diesel, gasoline, and LPG. CNG burns at higher temperatures and is cleaner than coal and other fossil fuels. The CEG team has constructed thousands of CNG filling stations worldwide to fuel cars and trucks worldwide.

QUAD GENERATOR ELECTRICITY, HEAT, COOL, AND CO2

Combined Heat and Power (CHP) is a high-efficiency energy cogeneration process producing simultaneously electrical and thermal energy from a single source of energy in a single system. With the same fuel source (natural gas, renewable gas, hydrogen), a CHP can produce electricity and heat, capturing as much as 90% of the fuel energy into useful output.

The electricity is produced by the combustion engine producing low voltage electricity through an alternator and transformed to medium voltage electricity up to 15kV. The thermal energy is captured from the specially designed engine cooling system and the muffler exhausts. The engine cooling fluid heat exchanger produces hot water, and 400C flue gas produces superheated steam.

CHP Cogeneration is an independent producer of electrical energy ideal for places frequently affected by blackouts, or energy-intensive facilities, such as industrial and service industries, which require massive heating, cooling, and electricity.

By capturing heat otherwise lost, CHP has a high performance and efficiency of around 90%. A typical diesel generator, for example producing only electricity, runs at about 40% efficiency. CHP, as a result, reduces energy costs and CO2 emissions compared to two processes separately producing electricity and heat. Our partner AB Gruppo engineered compact factory-integrated highly efficient CHP units up to 4.4 MW that can be shipped in container size and installed relatively quickly on-site.

Our solution is a quad-generator (4G) process. In addition to electricity and heat, we integrate additional equipment to convert heat into colling and sequester the CO2 gas. So, with the same fuel source and equipment, a 4G system can produce electricity, heat, cooling, and CO2. As an integrated system, our 4G solution can safely, continuously, and reliably convert a fuel source into useful production into 4 separate outputs. When considering cooling is typically produced by an electrical chiller requiring electrical energy consumption and pure CO2 as agriculture greenhouse feedstock typically purchased from gas companies, a 4G system is highly efficient, environmentally friendly, and offers long-term economic benefits. Our 4-in-1 solution provides breadth and flexibility to meet our customer’s operational requirements.

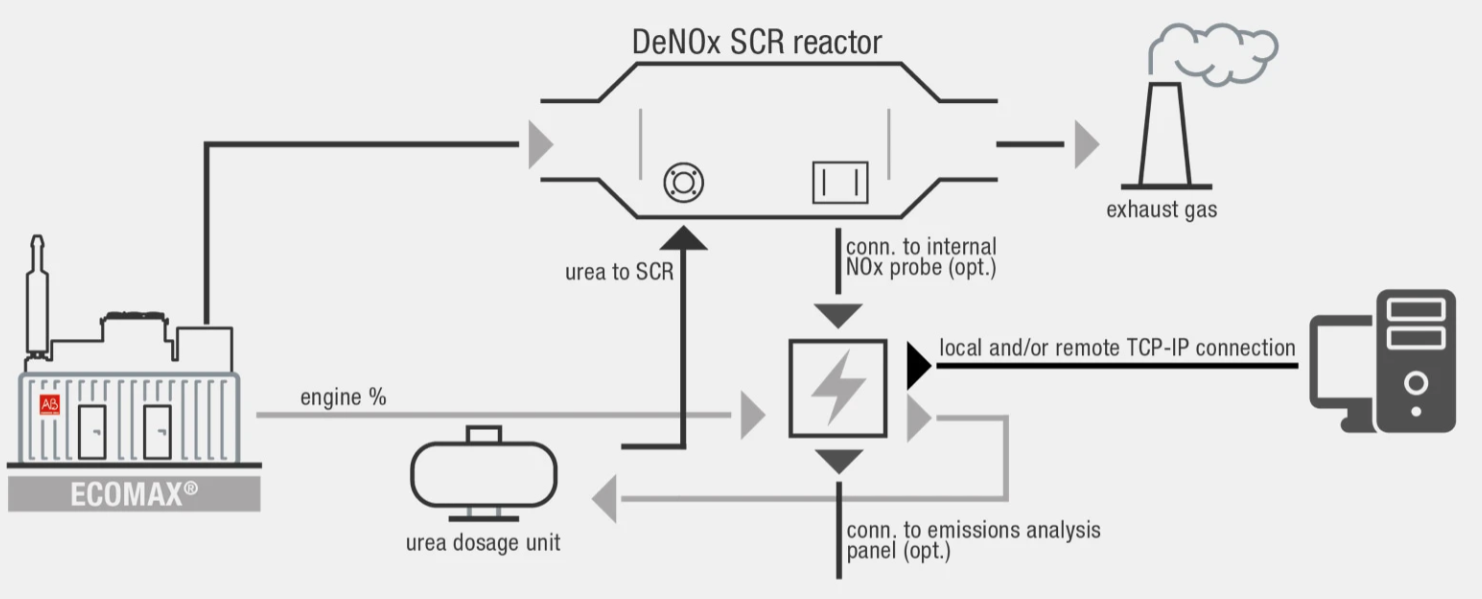

We clean and capture the exhaust gas from our generator fueled by natural gas or biogas using a state-of-the-art Selective Catalytic Reduction (SCR). An SCR reactor ensures that emissions comply with regulatory requirements. SCR is the most effective technology to neutralize nitrogen oxide NOx typically produced in fuel combustion. The SCR is sized to ensure maximum NOx abatement efficiency.

The heat is converted using an absorption chiller into chilled water. An absorption chiller works by heating mixtures of substances, typically water-ammonia or water-LiBr Lithium Bromide, as an evaporator and condenser or absorption and desorption system. Water act as the refrigerant, while LiBr is the absorber. This system is in thermal equilibrium with each other and is kept in a vacuum. Adding a heat source on one end to separate the mixture and an endothermic process at the other end when recombining produces cooling. It is analogous to skin cooling when sweat evaporates on hot days. The system is fully enclosed and sealed with only a heat source heat exchanger at one end and a chilled water heat exchanger at the other. Depending on the COP, the chilled water can be as low as 4C. Ammonia absorbent can achieve a much lower temperature. Our partner Enrgistx manufactures high-efficiency absorption chillers powered by hot water, steam, and natural gas with capacities of up to 1700 tons and COP of 1.6.

Our 4G solution delivers electricity, heating, cooling, and CO2 in a single solution. In combination with an agriculture greenhouse industry or CO2 sequestering processes, such as beverage carbonization or biopolymer, we could deliver net-zero or even carbon-negative solutions with RNG. Our compact footprint and modularity allow flexibility, ease of installation plug-and-play, and expansion as needed, depending on electrical and thermal requirements.